Yamaha Motor Europe

Robotics Business

Yamaha Intelligent Machinery Solutions: SMT & FA Section

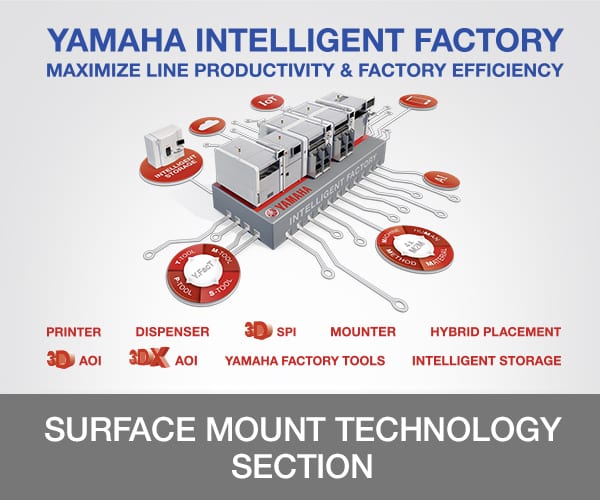

Yamaha Motor Robotics Business comprises the Surface Mount Technology Section (SMT Section) and Factory Automation Section (FA Section), each leveraging Yamaha’s expertise in industrial process automation to overcome the challenges manufacturers encounter to assemble electronic products and general industrial products.

read moreRobotics Assembly Business SMT & FA Yamaha Intelligent Machinery Solutions

The FA Section draws on Yamaha’s heritage in lean and efficient processes for the automation of motorcycle manufacturing to create state of the art robotics systems for high-speed precision assembly tasks across a wide range of industries from microelectronics to consumer products, food production, the automotive and aerospace businesses, and more. Yamaha supplies a complete selection of robots that covers all industrial types, from the simple linear robot to cartesian, SCARA, and articulated robots, and the flexible LCM100 conveying system, which is unique to Yamaha. Our comprehensive portfolio of robot technology provides everything you need to achieve a complete automation system as a robot assembly cell, or introduce an efficient robot transport system or handling system to assist a conventional production line.

Yamaha Intelligent Machinery Solutions Robotics Assembly Business SMT & FA

The selection of robot controllers offers compatibility with popular industrial Ethernet and fieldbus protocols. These include PROFINET, EtherNet/IP, EtherCAT, PROFIBUS, CC-Link, DeviceNet, and EtherNet/IP. Special Yamaha accessories help unleash the maximum performance from your robot assembly and include the iVY 2 vision system, electric grippers, and graphical robot programming and editing tools that simplify and accelerate setup.

Latest News Releases

Robotics Assembly Business SMT & FA Yamaha Intelligent Machinery Solutions

14. September 2020

Yamaha appoints Etama to distribute industrial robotics portfolio in Baltic region

Etama brings synergistic product portfolio and strong presence in Lithuania, Latvia, and Estonia to grow business for advanced automation. Yamaha Motor Europe Factory Automation section, …

NEWS RELEASE - FA

07. September 2020

Yamaha reveals robot flexibility boost with software pack for Asycube vibration

RCX320/340 plugin integrates Asycube with SCARA and cartesian robots, sharpens pick-and-place flexibility with Yamaha RCXiVY2+ non-stop vision Yamaha Motor …

NEWS RELEASE - SMT

23. June 2020

Yamaha reveals new connected showroom and remote support solutions in Europe

New connected services for sharing latest technologies, technical training, and field support. Yamaha Motor Europe SMT Section has setup an online demonstration room …